Drive Productivity: Upgrading Your Construction Equipment with Costs Komatsu Undercarriage Parts

Drive Productivity: Upgrading Your Construction Equipment with Costs Komatsu Undercarriage Parts

Blog Article

Explore Undercarriage Parts for Your Machinery Demands

Recognizing the components that make up the undercarriage and the value of choosing the best parts is key to ensuring smooth procedures and cost-efficient upkeep. As we discover the globe of undercarriage parts for machinery demands, a deeper insight right into the intricacies of this vital system will certainly unravel, dropping light on the foundation that supports the performance of your tools.

Relevance of Undercarriage Upkeep

Regular upkeep of undercarriage parts is crucial for guaranteeing optimal efficiency and longevity of equipment. The undercarriage of heavy tools, such as excavators, excavators, and track loaders, plays a vital role in supporting the weight of the maker, giving stability on numerous surfaces, and permitting smooth procedure - komatsu undercarriage parts. Ignoring undercarriage upkeep can lead to costly repairs, lowered performance, and prospective security risks

Regular assessments of undercarriage parts, such as track chains, rollers, idlers, and gears, are important to recognize damage at an early stage. Dealing with concerns without delay can prevent further damage to the undercarriage and various other parts of the equipment. Appropriate cleaning of undercarriage parts is also necessary to get rid of dirt, particles, and various other impurities that can speed up wear and rust.

Regular lubrication of undercarriage components is another vital aspect of upkeep to make sure smooth motion and reduce friction between parts. In addition, tracking the usage hours and maintaining upkeep records can assist in organizing prompt substitutes and extending the general life-span of the equipment. By focusing on undercarriage upkeep, equipment owners can optimize performance, reduce downtime, and inevitably reduce repair prices over time.

Kinds Of Undercarriage Components

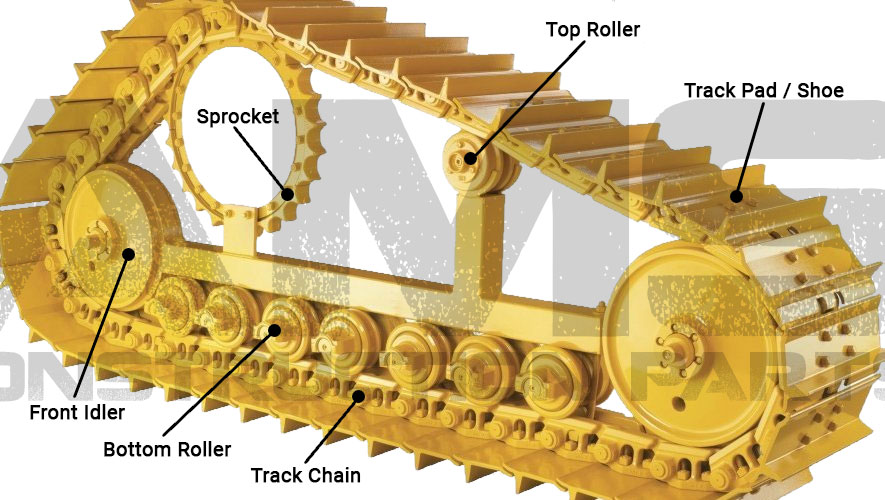

Upkeep of undercarriage parts is important for equipment longevity; comprehending the various kinds of undercarriage parts is important for reliable maintenance practices. Undercarriage components vary relying on the kind of machinery and its desired use. Common types of undercarriage parts include track chains, track footwear, rollers, idlers, sprockets, and track frameworks.

Track chains are accountable for driving the equipment ahead and sustaining the weight of the tools. Track frameworks serve as the foundation for the whole undercarriage setting up, linking all the elements with each other.

Regular evaluation and upkeep of these undercarriage parts are important to prevent pricey repairs and downtime. By comprehending the function of each sort of undercarriage part, equipment drivers can make sure optimal performance and expand the life-span of their devices.

Aspects to Take Into Consideration When Selecting Components

Another crucial factor is compatibility with the certain equipment design. Each item of machinery might have distinct demands for undercarriage components, consisting of dimension, layout, and specs. Guaranteeing that the components work with the machinery will certainly help stop operational problems and premature wear.

Additionally, it is vital click this site to consider the operating conditions in which the equipment will certainly be made use of. Variables such as terrain, weather, and usage frequency can all tear and impact the wear on undercarriage parts. Picking parts that are developed to stand up to the particular operating conditions can assist lengthen the life of the equipment and reduce upkeep prices over time.

Advantages of High-Quality Undercarriage Components

Top quality undercarriage parts play an essential function in improving machinery efficiency and prolonging its operational durability. By buying excellent undercarriage components, machinery operators profit from raised sturdiness and dependability. One of the key benefits of using high-quality undercarriage components is enhanced performance. These parts are designed to hold up against hefty loads, severe terrains, and requiring functioning problems, making sure that the machinery runs at its ideal degree without regular breakdowns or malfunctions.

Furthermore, high-grade undercarriage components add to set you back financial savings in the future. While the initial investment may be greater compared to common parts, the longevity and longevity of premium components lower the demand for check over here regular replacements and repair services. This not only decreases downtime however also lowers maintenance costs, eventually bring about higher total efficiency and earnings for businesses that rely upon hefty equipment.

Additionally, exceptional undercarriage parts enhance safety and security by lowering the risk of unforeseen failings or mishaps. The boosted stability and performance offered by premium parts produce a safer working setting for equipment drivers and those functioning in close closeness to the devices. Ultimately, selecting top notch undercarriage components is a strategic decision that generates numerous benefits in regards to efficiency, cost-efficiency, security, and longevity.

Tips for Expanding Undercarriage Lifespan

To make the most of the durability of undercarriage components for equipment, carrying out positive treatment methods is crucial for ensuring optimal performance and toughness. Frequently examining the undercarriage components for signs of damage, such as worn-out tracks, loosened screws, or damaged rollers, is vital. Attending to these issues without delay can protect against additional damage and extend the life-span of the undercarriage. Furthermore, keeping correct track stress is crucial to lower early wear on the parts. Over-tightened tracks can result in raised anxiety on the undercarriage, while loose tracks can trigger misalignment and unequal wear.

Moreover, keeping the undercarriage clean from dirt, particles, and various other impurities can dramatically impact its lifespan. Collected debris can speed up wear and deterioration, influencing the overall efficiency of the equipment. On a regular basis cleansing the undercarriage with a pressure washer or a brush can aid prevent these issues. Finally, running the equipment within recommended standards, such as preventing too much rates or overloading, can likewise add to extending the undercarriage life-span. By following these tips, equipment owners can make certain optimum performance and sturdiness of their undercarriage components.

Conclusion

Finally, preserving the undercarriage components of equipment is important for optimum efficiency and longevity. By comprehending the different types of undercarriage parts and factors to consider when selecting them, businesses can guarantee their devices runs effectively. Investing in premium undercarriage components not just improves performance however likewise minimizes downtime and expensive repair work. By complying with appropriate upkeep practices, businesses can extend the life expectancy of their undercarriage parts, inevitably saving time and cash over time.

Regular upkeep of undercarriage parts is important for guaranteeing optimum efficiency and durability of machinery.Upkeep of undercarriage components is crucial for her comment is here equipment long life; comprehending the various kinds of undercarriage parts is critical for effective maintenance techniques.When selecting undercarriage parts for machinery, it is crucial to consider various aspects to make certain optimal performance and long life.To take full advantage of the durability of undercarriage parts for machinery, applying positive care methods is vital for ensuring ideal efficiency and sturdiness. By following these suggestions, equipment proprietors can guarantee ideal efficiency and sturdiness of their undercarriage components.

Report this page